Air conditioner compressors are an integral part of your HVAC system. They help regulate the temperature and airflow within your home, providing comfort during hot summer months. But what happens when the AC compressor clutch goes bad? How can you tell if it’s time for a replacement? In this article, we’ll explore the signs that indicate a failing compressor clutch, how to diagnose the issue, and what you can do to stay cool and comfortable. Keep reading to learn more.

Tabe of Contents

- 1. What is an AC compressor clutch and why is it important?

- 2. Symptoms of a bad AC compressor clutch

- 3. Testing the electrical components of the AC compressor clutch

- 4. Inspecting the mechanical components of the AC compressor clutch

- 5. Replacing a bad AC compressor clutch: DIY or leave it to the pros?

- People Also Ask:

- Conclusion:

1. What is an AC compressor clutch and why is it important?

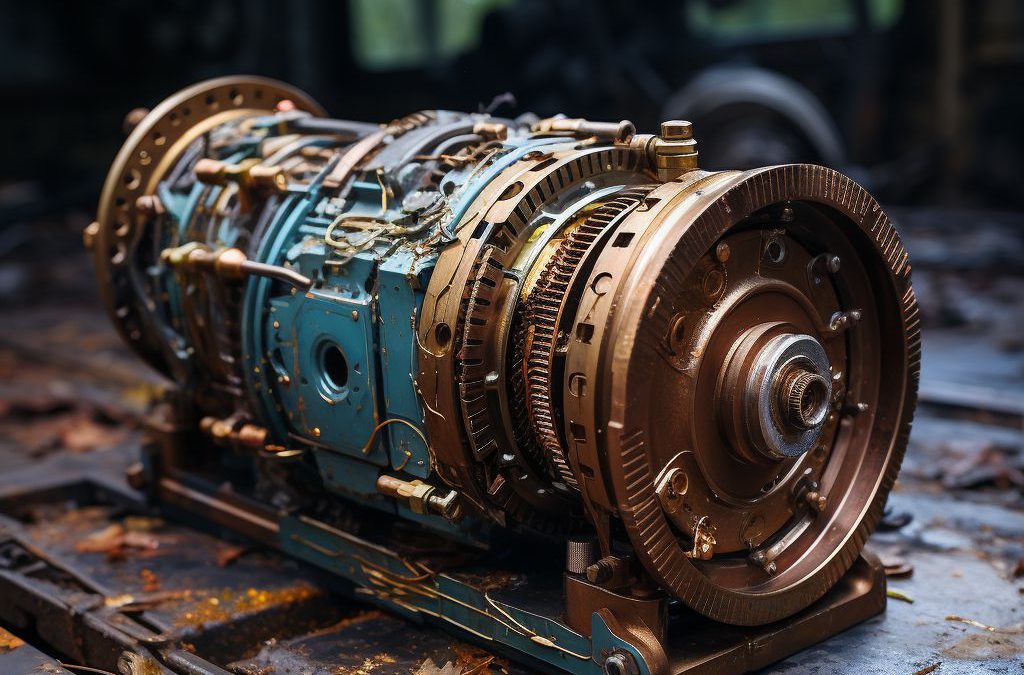

The air conditioning system in your vehicle is made up of several components, one of which is the AC compressor clutch. It is a small but important part of the AC system, as it engages and disengages the AC compressor. The compressor is responsible for compressing and circulating the refrigerant gas that keeps your car cool in hot weather.

The AC compressor clutch is mounted to the front of the compressor, with a pulley attached to it that is driven by a belt connected to the engine’s crankshaft. The clutch consists of a rotor, an electromagnetic coil, and a set of springs and bearings which all work together to engage and disengage the compressor.

So why is the AC compressor clutch so important? For starters, it is the primary source of power for the AC compressor. Without a functioning clutch, the compressor won’t receive the power it needs to circulate the refrigerant throughout the system. This means that your AC will stop blowing cold air, leaving you hot and uncomfortable on a muggy day.

In summary, the AC compressor clutch is a critical component of your vehicle’s air conditioning system. Its primary function is to engage and disengage the compressor as needed, ensuring that the system functions properly. If the clutch is bad, it can cause a range of problems that can impact the performance of your AC system.

2. Symptoms of a bad AC compressor clutch

The AC compressor clutch plays a key role in the operation of your air conditioning system. A bad AC compressor clutch can cause your AC system to malfunction or stop working completely. Here are some symptoms that may indicate a bad AC compressor clutch:

- AC system blowing hot air: If you notice that your AC system is blowing hot air instead of cold, it could be a sign that your AC compressor clutch is not working properly.

- No cool air: If the air coming out of your AC vents is not cool enough, or is not as cool as it used to be, it may be a sign of a bad AC compressor clutch.

- Loud noises: A damaged AC compressor clutch can cause strange noises like screeching, grinding, or rattling. If you hear any of these sounds, it’s best to get your AC system checked by a professional.

If you notice any of these symptoms, it is important to get your AC system checked as soon as possible to prevent further damage. In the next section, we will discuss how to test the electrical and mechanical components of your AC compressor clutch.

3. Testing the electrical components of the AC compressor clutch

The electrical components of the AC compressor clutch are responsible for providing power to the clutch so that it can engage and disengage the compressor. When the electrical components fail, the clutch may not engage or it may engage and stay on even when the AC is turned off.

To test the electrical components of the AC compressor clutch, you need a multimeter set to measure DC voltage. Start by testing the voltage across the clutch coil terminals. With the engine running and the AC turned on, the voltage should be between 12 and 14 volts. If there is no voltage, check the AC compressor clutch relay and fuse. If they are okay, the problem could be with the wiring or the AC control module.

Next, test the resistance of the clutch coil. Disconnect the electrical connector from the clutch and measure the resistance across the two pins. It should be between 3 and 5 ohms. If it is outside this range, replace the clutch.

Another way to test the clutch coil is to apply battery voltage directly to it. Disconnect the electrical connector from the clutch and connect a jumper wire from the positive battery terminal to one of the clutch pins. Connect another jumper wire from the negative battery terminal to the other clutch pin. If the clutch engages, the coil is good.

Note: Always be careful when working with electrical components. Disconnect the battery before testing or making repairs. Follow proper safety precautions and consult a professional if you are unsure or uncomfortable with .

4. Inspecting the mechanical components of the AC compressor clutch

can help you confirm if it’s indeed not working properly. The most common issue with the mechanical aspects of the AC compressor clutch is the presence of cracks on the surface of the clutch plate. Over time, the surface of the clutch plate may wear out and develop cracks due to long-term use, leading to significant clutch slippage or even complete failure.

Another telltale sign that the mechanical components of the AC compressor clutch may be bad is the presence of burnt or damaged wiring and connectors. The electrical connector and wiring is responsible for supplying power to the clutch, and if it gets burned or damaged, the clutch won’t be able to receive the necessary power it needs to function properly.

Lastly, checking the pulley system can also provide some insight into the mechanical components of the AC compressor clutch. Check if the pulley system turns freely and smoothly. If it doesn’t, it may indicate that the bearings are worn out and need to be replaced.

If you observe any of these symptoms during your inspection, it’s best to consult an HVAC professional to fix the issue. These inspections require a bit of technical know-how, and you don’t want to damage the AC compressor or any other components if you try and DIY the fix.

5. Replacing a bad AC compressor clutch: DIY or leave it to the pros?

When it comes to replacing a bad AC compressor clutch, the decision to do it yourself or seek professional help will depend on your level of expertise and comfort with mechanical work. It’s worth considering some of the pros and cons of each approach before making a decision.

DIY

If you’re a skilled DIYer with experience in automotive mechanics, replacing the AC compressor clutch yourself can save you money on labor costs. However, it’s important to ensure that you have the right tools and equipment, as well as access to manufacturer-specific repair manuals and diagnostic equipment, in order to properly diagnose and replace the faulty clutch.

It’s also worth noting that working on your own car can be time-consuming and potentially dangerous if you don’t have the right skills or experience. If you’re not confident in your ability to safely and accurately perform the necessary repairs, it’s best to leave it to the professionals.

Leave it to the pros

For those who want peace of mind and a guarantee of quality, a licensed and experienced HVAC technician is always the best choice. With the expertise and equipment to quickly and accurately diagnose and repair your AC compressor clutch, a professional can ensure that your system is in top working order and save you from potentially costly mistakes caused by improper repairs.

Additionally, many HVAC professionals offer warranties on parts and labor, so you can rest assured that your investment is protected. While you may pay more upfront for professional services, the safety, efficiency, and long-term performance of your HVAC system make it a worthwhile investment.

People Also Ask:

What are the signs of a bad AC compressor clutch?

The most common sign of a bad AC compressor clutch is when you turn on the AC and it blows hot air. Other signs include strange noises coming from the compressor, vibration felt while the AC is on, and a burning smell.

How do I test my AC compressor clutch?

To test your AC compressor clutch, turn the engine on and turn the AC to its coldest setting. Observe the clutch while it engages and disengages. If it does not engage at all or engages but does not spin properly, it may be bad.

Can a bad AC compressor clutch cause a car not to start?

If the clutch is completely locked up, it can cause the engine to not start. This is because the compressor puts an extra load on the engine when the clutch is engaged. However, if the clutch is just slipping or not engaging properly, it should not affect the engine starting.

How much does it cost to replace an AC compressor clutch?

The cost of replacing an AC compressor clutch can vary depending on the make and model of your vehicle. Typically, it can cost anywhere from $300 to $1,000.

Can you drive with a bad AC compressor clutch?

It is not recommended to drive with a bad AC compressor clutch. Doing so can cause damage to other parts of the AC system and can ultimately lead to a more expensive repair.

Conclusion:

If you suspect that your AC compressor clutch may be bad, it is important to have it checked by a professional. Ignoring the issue can lead to further damage and a more costly repair. Signs to look out for include hot air blowing from the AC, strange noises, vibration, and a burning smell. In some cases, a bad clutch can even cause the engine to not start.

Customer Care Representative

Leo is committed to ensuring unparalleled client satisfaction. His dedication to addressing customer concerns and inquiries reflects our commitment to service excellence.